onze panelen

SYMPHONY

SYMPHONY PLUS

EXPLANATION OF THE CELL TECHNOLOGY

How are heterojunction cells different from other solar cells, especially the well-established crystalline and thin-film cells?

Conventional crystalline or thin-film cells are usually made of one material, such as polycrystalline or monocrystalline wafers, or a copper-indium-gallium-selenide compound, for example in the thin-film type CIGS. Each of these technologies has its specific advantages. For example, crystalline cells can convert more direct sunlight into electricity than thin-film cells.

Thin-film cells, on the other hand, perform better in low light. This means that they generate more electricity in times of diffuse light, for example when it is cloudy or the irradiation is affected by smog, but also in the morning and evening. They also have an advantage in terms of temperature, as shown by the temperature coefficients. The temperature coefficient of a solar cell or module indicates by how much the output and thus the efficiency decreases per degree Celsius rise in temperature. The smaller the temperature coefficient, the less the efficiency decreases as the temperature increases.

Thin film cells have a smaller temperature coefficient than crystalline modules and therefore lose less power at higher temperatures.

PhaseLux combines crystalline and thin-film technology.

PhaseLux’s heterojunction cells combine the advantages of both technologies by incorporating both crystalline and thin-film technology.

In HJT solar cells, a thin monocrystalline silicon wafer is surrounded by an ultra-thin amorphous (= thin film) silicon layer.

PhaseLux is also one of the few module manufacturers to use n-type wafers. Conventional monocrystalline wafers are based on the p-type, while PhaseLux uses the n-type because it is less sensitive to impurities.

WHY GLASS-GLASS PANELS

In PhaseLux glass-glass solar panels, the solar cells are enclosed between two layers of glass. In other solar panels, the front is often glass and the back is plastic.

The double glass layer in glass-glass solar panels offers many advantages such as higher performance and better and long-lasting quality, resulting in a very long warranty period.

The advantages of glass-glass solar panels:

- Resistant to extreme weather, such as heavy hailstorms and heavy snowfalls

- Lower temperature coefficient

- Up to 25% higher power output

- Up to 350% longer warranty period and the best warranty conditions

- Fire safe, as glass is virtually incombustible

- The risk of micro-cracks is almost zero

- High-end design, production and control

- Exceptionally long service life of many decades

35 year all-risk insurance warranty is housed at ArielRe.

This is a Lloyds underwriter.

The All-Risk insurance guarantee is free and transferable upon registration with PhaseLux.

WHY LIGHTWEIGHT

PhaseLux has worked with glass fabricators to reduce glass thickness to 2 x 1.6 mm while maintaining strength and resistance to static and dynamic loads. This promotes light/energy transmittance and therefore efficiency. Efficiency is also positively impacted because heat retention in the glass itself is lower due to the reduced glass mass.

The panels also meet the lifting standards of occupational health and safety legislation. In practice, this not only brings labor benefits to installers, but also gives engineers more freedom because the static weight load on the structure is positively affected, becoming a less restrictive factor.

DESIGN

There are many aspects to consider when designing a product, and one important guideline is the LCOE (levelized cost of electricity). So energy is needed to produce a solar panel (electricity).

This solar panel will then produce its own energy over a long period of time. Lifetime and efficiency have an important impact on LCOE. This is because if the lifetime is longer than normal and also the efficiency is higher than normal, then in many cases the LCOE will decrease.

These values (and many others) are included in a calculation, the result of which is a factor. PhaseLux finds the balance here to keep this LCOE factor as low as possible.

Fire protection is also a very important factor. In most cases, external factors are the cause of the fire and not the panels themselves. What is common, however, is the spread of fires when external fire is caused by solar panels with film. PhaseLux has therefore decided to design only panels that have a glass panel on the front and back (most available panels do not have a glass panel on the back, but a special film that is much more sensitive to fire).

In the design and quality controls throughout the process, we also eliminate the risk of fire development of the system itself.

PRODUCTION

We now have a product that has been extensively tested and is ready for production. To ensure high quality here as well, PhaseLux has independent parties regularly inspect and report on the entire production process in addition to the normal quality tests required for certification (regularly recurring sample).

This involves checking and reporting on the components used, the production environment, the actual production, the post-production quality test, the packaging and finally the loading of the products.

TRANSPORT

An often underestimated risk for quality degradation is the transportation of products.

PhaseLux is very aware of this and has taken it into consideration when designing packaging and through a unique collaboration with SolarTester.

This is a reputable independent party that performs extensive and unique quality checks at locations throughout Europe.

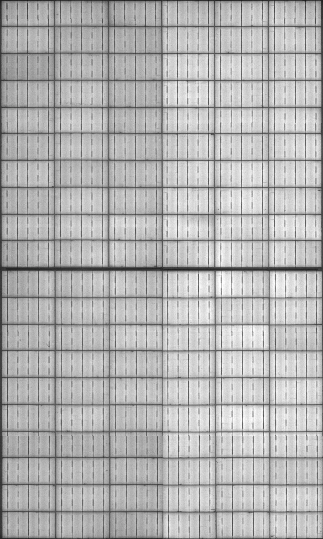

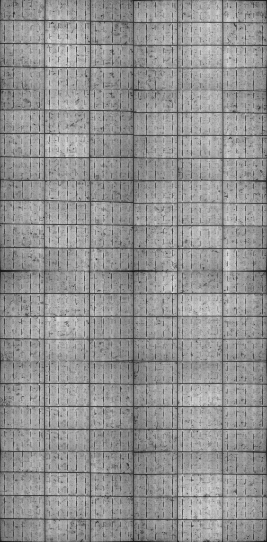

High-resolution electroluminescence is then used to examine whether Microcracks have occurred during charging and transportation. Microcracks are small cracks in the solar cells that are not visible to the naked eye.

Since we have already chosen glass-glass panels, the likelihood of this happening has already been greatly reduced.

A test that involves taking a type of x-ray of the panel can be used to determine if micro-cracks are present.

EXAMPLE OF A GOOD PANEL

EXAMPLE OF A PLATE WITH MICROCRACKS

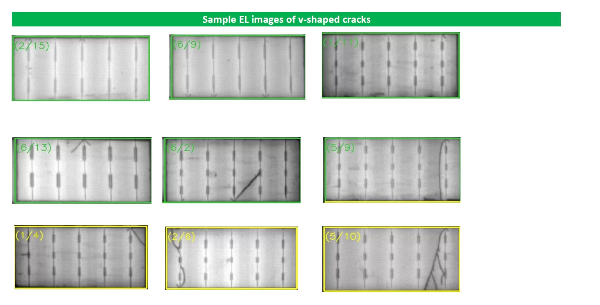

Another test is then carried out to check for V-cracks. This involves it is checked whether all connections that are supposed to conduct current are still intact.

Finally, it is measured whether all cell string diodes are functioning according to specifications. Cell string diodes are electronic components located in the small boxes on the back of the of the control panel. They ensure that the current is automatically diverted when a part of the panel is temporarily shaded. This prevents damage caused by internal heating of the cells (hotspots).

When the module is approved, it receives a SolarTester sticker and is neatly packed back into the pallet. So it is possible that in the future you will find a module with the SolarTester sticker. Then you know that the quality is ok.

PhaseLux is currently the only supplier in Europe that works according to this comprehensive quality procedure.

ASSEMBLY

- Working according to the principle “We know the state of the art”.

- Achieving a high return on investment after installation.

- Installation in accordance with the requirements of building standards, so you do not have to deal with the authorities, discussions, for example, with local authorities.

- Not only the product quality, but also the system quality is guaranteed.